-

We’re On Call 24/7 : +8613538296050

-

E-mail : anna@rohoconnector.com

We’re On Call 24/7 : +8613538296050

E-mail : anna@rohoconnector.com

It is especially important to select a suitable N type connector in the establishment of the radio antenna feeder system. How has selected medium and small power with threaded connection mechanism in the construction of the previous relay station antenna feeder system. Connector.

In the past, we chose a medium and small power N type connector with a threaded connection mechanism in the construction of the relay station antenna feeder system. This connector can be interchanged with the international NG-type products. It has the characteristics of high frequency bandwidth, excellent performance, high reliability and long life.

N type straight connector

The N type connector is used as a terminal device to connect to coaxial cables, printed circuit boards (PCBs) or terminal blocks. The manufacturers are manufactured in accordance with precision RF and microwave industry technical standards.

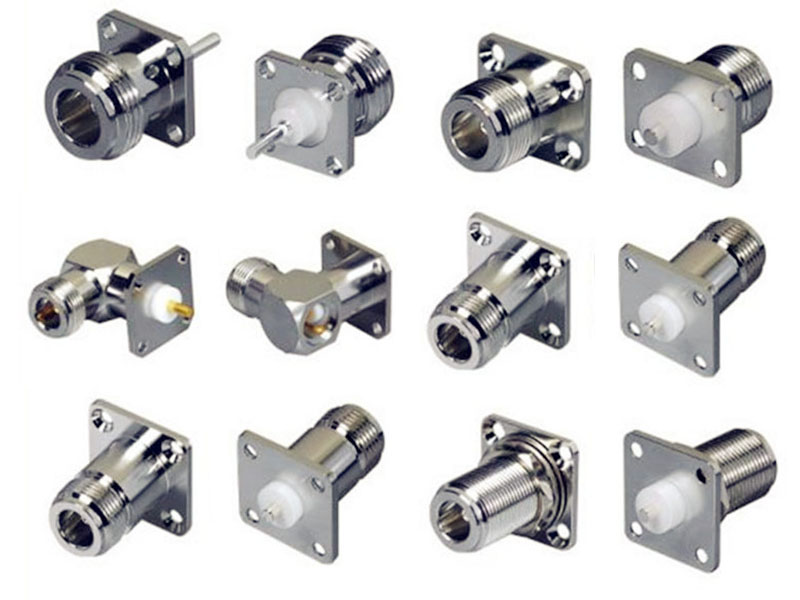

The structure is divided into male or female, and the style has standard polarity or reverse polarity. The shape of the N type connector is divided into straight or right-angle type and its 4-hole flange type, press-in type, diaphragm type, 2-hole panel type, 4-hole panel type or free type.

Termination methods are snap/weld, snap/weld (static contact), crimp/weld, field replaceable, solder or solder/weld. The N type connectors used in the construction of the relay station antenna feeder system are classified into standard performance or high performance grades, and the bulk material is brass or stainless steel.

Reverse polarity N-type plug

Divided into 50 ohm impedance and 75 ohm impedance, 50 ohm N type connector frequency up to 12 GHz and high reliability coaxial connector with screw locking system. These two connectors cannot be connected to each other.

The N type connector uses a medium-sized screw-on locking system with high weather resistance. In addition, the N type connector has the advantages of high robustness and high reliability, as well as excellent intermodulation performance.

Each connector has military standards and commercial standards. Military standards are generally copper, PTFE insulated, gold-plated inside and outside, the most reliable performance, of course, the cost is higher; commercial standard design uses cheap materials, such as brass castings, polypropylene Insulation, silver coating, etc., the reliability is relatively poor.

The main body of the connector body is mostly brass, beryllium copper and stainless steel, and the center conductor is generally gold plated to ensure low resistance and corrosion resistance. Military standards require gold plating on SMA and SMB; N-type, TNC and BNC are silver-plated, but most customers prefer nickel plating because silver is more susceptible to oxidation.